sheet metal drawing operation is used to make

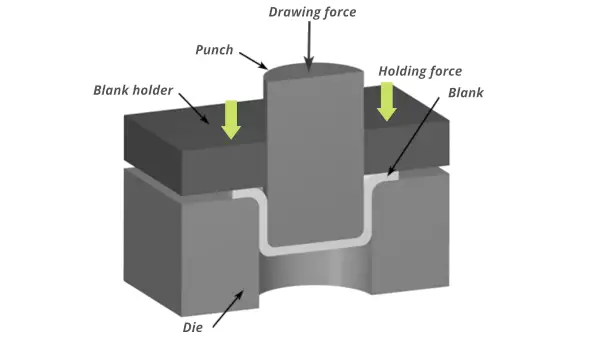

Easy Tool Modification Shorter Lead Times And Lower Tooling Cost With Quintus. The punch pushes the sheet metal blank downward and forces it into a die cavity which ultimately forms a shape of the desired part.

Deep Drawing An Overview Sciencedirect Topics

Sheet metal is one of the fundamental forms used in metalworking and it can be cut and bent into a variety of shapes.

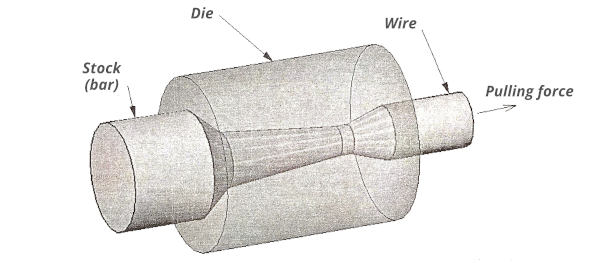

. Drawing is classified into two types. Sheet metal drawing operation is used to make A wire B tube C cup shaped parts D. Drawing is a metalworking process which uses tensile forces to stretch metal or glass.

As mentioned the punch and die setup is somewhat similar to a sheet metal cutting operation such as punching or blanking. It leaves a lean edge on the piece of metal that is sheared or cut. And the punch is hit at the other end of the sheet producing a shearing effect.

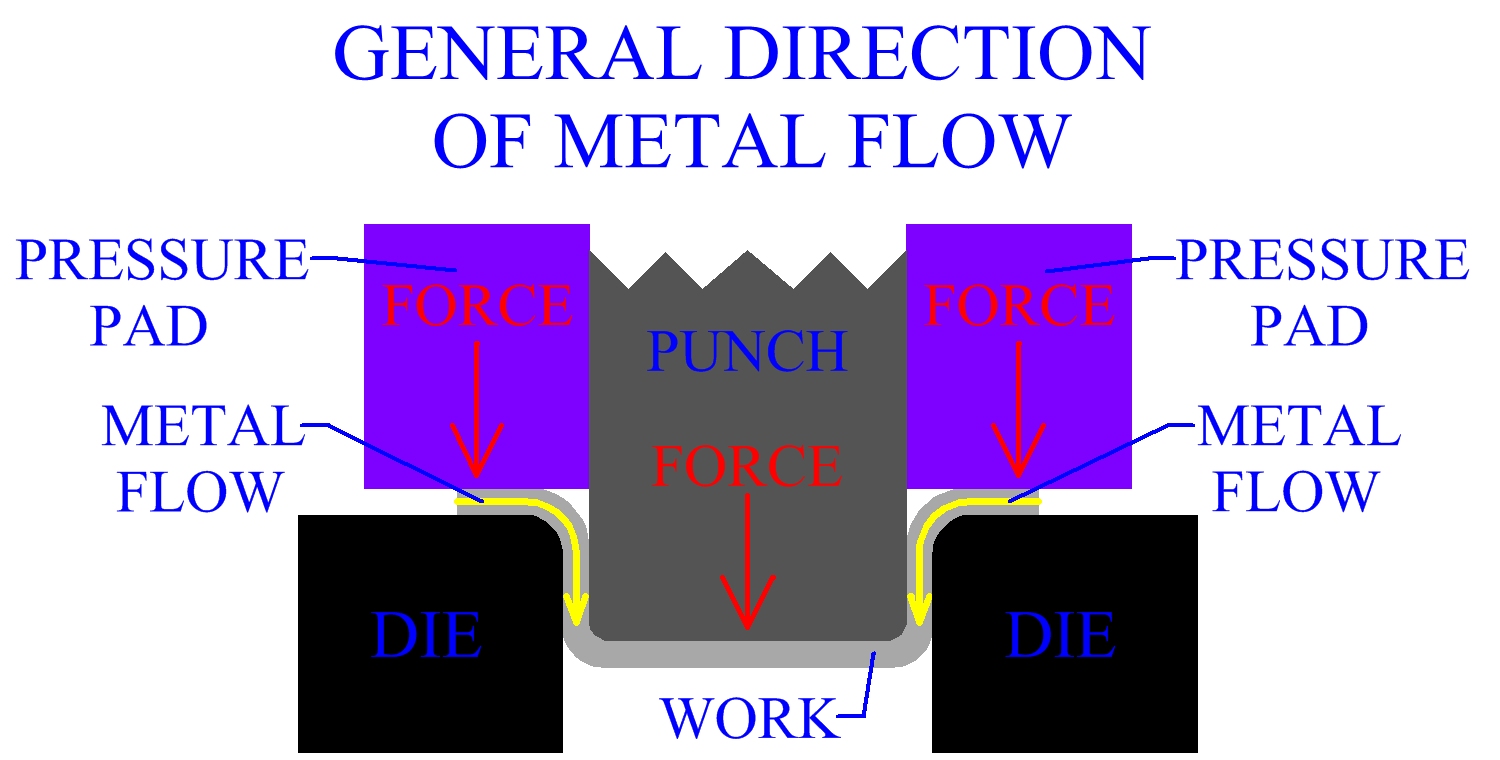

As the load applied through the punch the sheet metal is forced to flow radially and sink into the die cavity to form a cup. Course Title CS 2020. The process of deep drawing is shown in Fig.

A sheet metal drawing operation is used to form a cylindrical cup with inside diameter 75mm and height 50mm. Select the type of sheet metal operation. In general the upper limit of the drawing ratio is defined as 200.

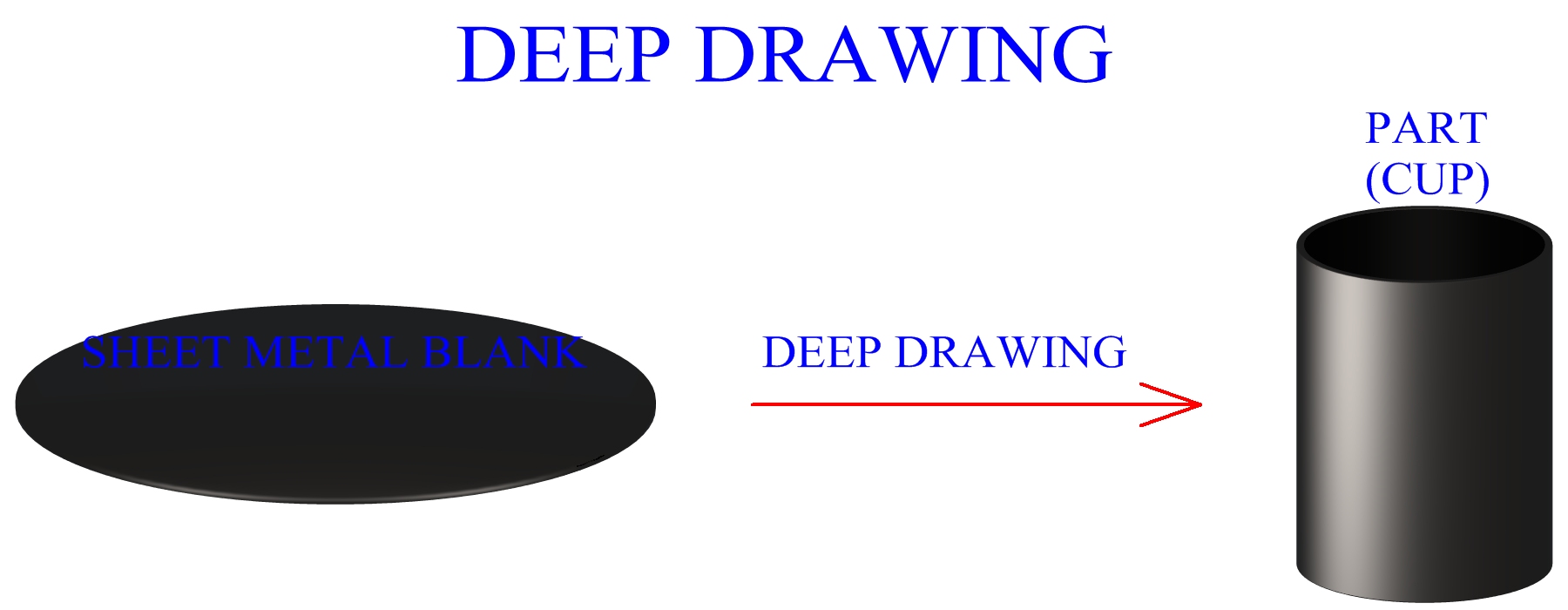

Drawing is a sheet-metal-forming operation used to make cup- shaped box-shaped or other complex-curved and concave parts. True False Coining is a bulk deformation process also used in sheet-metal work in which fine. Sheet metal drawing is defined as a plastic deformation over a curved axis.

It is a cut in a straight line across a strip sheet or bar. In this operation a sheet metal workpiece is placed or kept between two dies from one end. Drawing is a sheet metalworking operation used to produce cup-shaped or box-shaped or other complex-curved an concave parts.

School Atmiya Institute Of Technology. Our deeper draw capacity offers you completely customized options. The greater the ratio means a severe drawing operation.

Find Forms for Your Industry in Minutes. Ad Metalworking Fabrication Machinery Tooling and Accessories for All Industrial Shop Needs. What is the name of the tooling and b what is the name of the machine tool used in the operations.

Ad We create customized parts in the exact size shape and material you need. Ad Increase your capacity by up to 80 with Quintus high pressure metal forming. Extremely thin sheets are considered foil or leaf and pieces thicker than 6 mm 025 in are considered plate such as plate steel a class of.

Ad State-specific Legal Forms Form Packages for Metallurgy. It is usually measured as the difference between the final included angle of the bent part and the angle of the tooling used to make the bend divided by the angle of the tooling. Mechanics of Deep Drawing.

Forming process are particular manufacturing process which make use of suitable stresses like compression tension shear or combined stresses which cause plastic deformation of the materials to produce required shapes. During the deep drawing operation the tensile forces cause the sheet metal. Drawing is a sheet-metal-forming operation used to make cup-shaped box-shaped or other complex-curved and concave parts by placing a piece of sheet metal over a die cavity and pushing the metal into the cavity with a punch.

During the sheet metal drawing operation the tensile forces cause the sheet metal blank to plastically deform into a cup shaped part. Thicknesses can vary significantly. The process is best suitable for complex shaped problems.

The tooling is called a punch and die b the machine tool is called a. Drawing is a metalworking process that uses tensile forces to stretch elongate metal glass or plasticAs the metal is drawn pulled it stretches to become thinner to achieve a desired shape and thickness. Pages 100 This preview shows page 67 - 70 out of 100 pages.

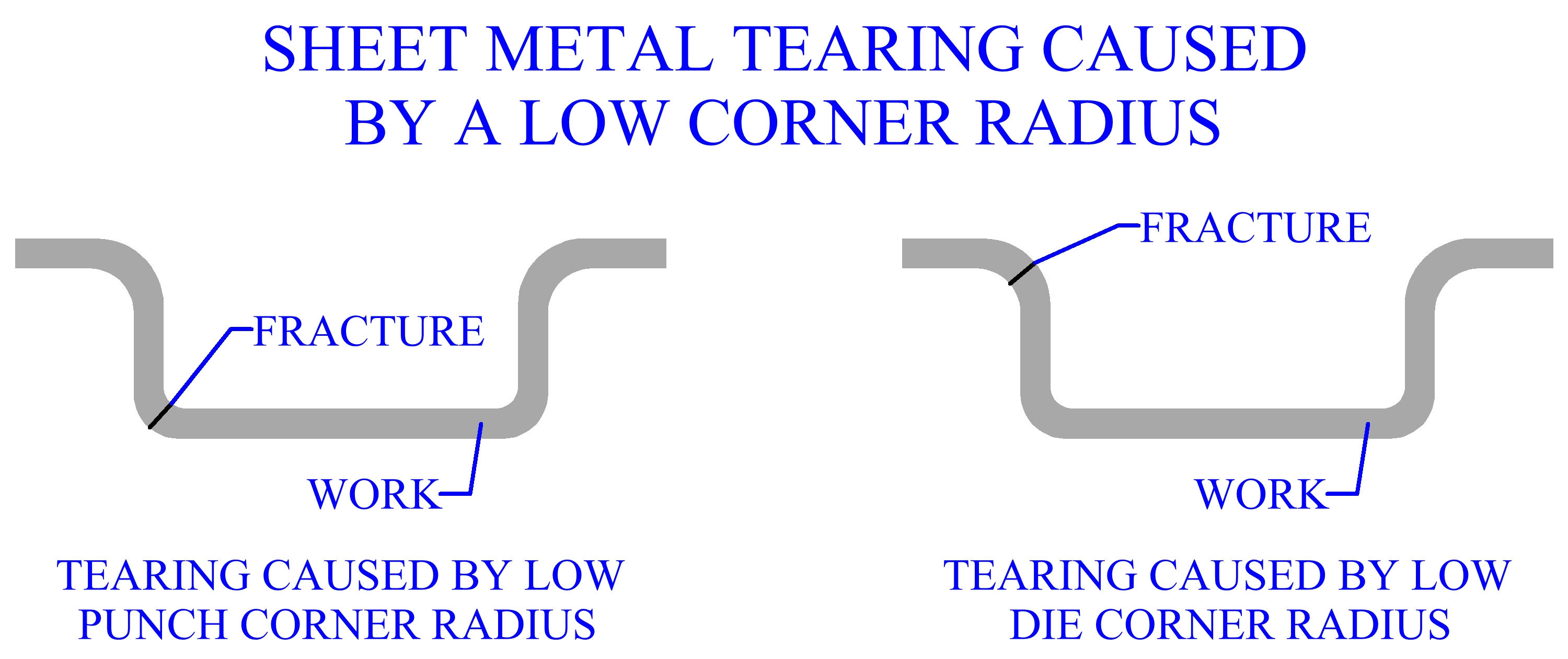

The Shearing operation is a cut in a straight line across a strip sheet or bar. The punch pushes the sheet metal blank downward and forces it into a die cavity which ultimately forms a shape of the desired part. Springback is the elastic recovery of the sheet metal after bending.

The draw die must have the shape of a funnel or cone to permit the sheet metal to be drawn properly into the die cavity. The mechanics of deep drawing process is shown in Fig. One of these calculations is the drawing ratio DR.

In conventional sheet metalworking operations a. Drawing is a sheet metalworking operation used to produce cup-shaped or box-shaped or. Two main factors will cause the punch in deep drawing to draw the metal into the die cavity rather than shearing it.

Deep drawing is a metal forming operation in which the sheet metal is stretched into a desired shape by the mechanical action of a punch. Deep drawing is a sheet metal forming process that involves complex material flow and force distributions. The deep drawing process is used to manufacture sheet metal parts in large volumes for various industries.

Streamlined Document Workflows for Any Industry. As the metal is drawn pulled it stretches thinner into a desired s. Drawing ratio is calculated as the ratio of blank diameter to punch diameter.

Sheet metal is metal formed into thin flat pieces usually by an industrial process. Sheet metal drawing operation is used to make a wire. Generally if the drawn part has depth more than its diameter then it is.

Figure 3-67 sheet metal drawing without blankholder. Sheet metal drawing and wire bar and tube drawing. New Used Machinery ft Benders Notchers Ironworkers Mills Saws CNC Presses More.

There are some basic calculations related to the severity of sheet metal drawing operations. Terms in this set 19 Identify the three basic types of sheet metalworking operations.

Deep Drawing Find Suppliers Processes Material

Deep Drawing Operation In Sheet Metal Smlease Design

Deep Drawing Operation In Sheet Metal Smlease Design

9 Different Types Of Sheet Metal Operations With Diagram Pdf

Die Basics 101 Fundamentals Of Drawing And Stretching

Sheet Metal Forming An Overview Sciencedirect Topics

What Is Metal Drawing Process Its 3 Types You Should Know

Deep Drawing An Overview Sciencedirect Topics

Smf Sheet Metal Forming Total Materia Article

What Is Involved In The Deep Drawn Manufacturing Process Hudson Technologies

Sheet Metal Forming Basics Processes And Material Used

What Is Metal Drawing Process Its 3 Types You Should Know